Ensuring Optimum Coolant Flow during Chemotherapy Treatment

- Published in Banksia Controls News

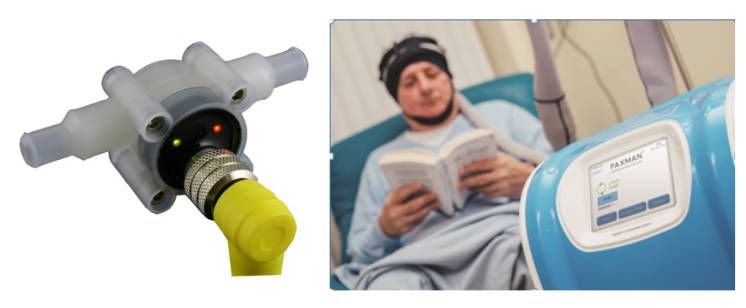

Titan Enterprises reports on how Paxman Coolers Ltd (www.paxmanscalpcooling.com) has enhanced their innovative Scalp Cooling System for chemotherapy treatment through integration of a Titan 800-Series flowmeter.

Paxman has been pioneering scalp cooling technology worldwide for over 25 years and are committed to improving the efficacy of scalp cooling for all cancer treatment patients across the world. The Paxman scalp cooler has been used by over 100,000 patients in 32 countries and is responsible for helping patients to keep their hair and retain normality during chemotherapy. The treatment works by lowering scalp temperature before, during and after the administration of chemotherapy. Hair loss is considered one of the most negative factors in a cancer patient’s care. About 65% of patients will undergo a chemotherapy that will cause hair loss. Therefore today approximately 4 million patients worldwide will lose their hair every year and by 2030 over 6.7 million patients will lose their hair without scalp cooling.

To address this challenge, Paxman Coolers Ltd. turned to Titan Enterprises to develop a flowmeter to monitor the rate of coolant flow around their patented cooling cap. Based upon their 800-Series turbine flowmeter – Titan Enterprises were able to provide Paxman with the technology to ensure that the coolant flow rate is kept within an optimum range to provide the patient with the best possible chance of keeping their hair.

Patrick Burke, Technical Manager of Paxman commented "We chose to integrate the Titan Enterprises 800 Series flowmeter into our Scalp Cooling System because it offered an excellent balance of measurement accuracy, long term resistance to coolant fluids, high reliability and proved easy to maintain”.

Operating over 6 flow ranges from 0.05 to 15 litres per minute, the Titan Enterprises 800 Series turbine flowmeter combines high performance and competitive pricing. Using totally non-metallic wetted components makes the 800 Series an ideal choice for the metering of corrosive chemicals in particular. For further information on the 800 Series turbine flowmeter please visit www.flowmeters.co.uk/pd_800series.htm or contact BanksiaControls on +61 3 5157 8309, or email This email address is being protected from spambots. You need JavaScript enabled to view it. , www.banksiacontrols.com.au